Watching The Horologists INF385T Design Synthesis

Interaction Diagram and Transcript

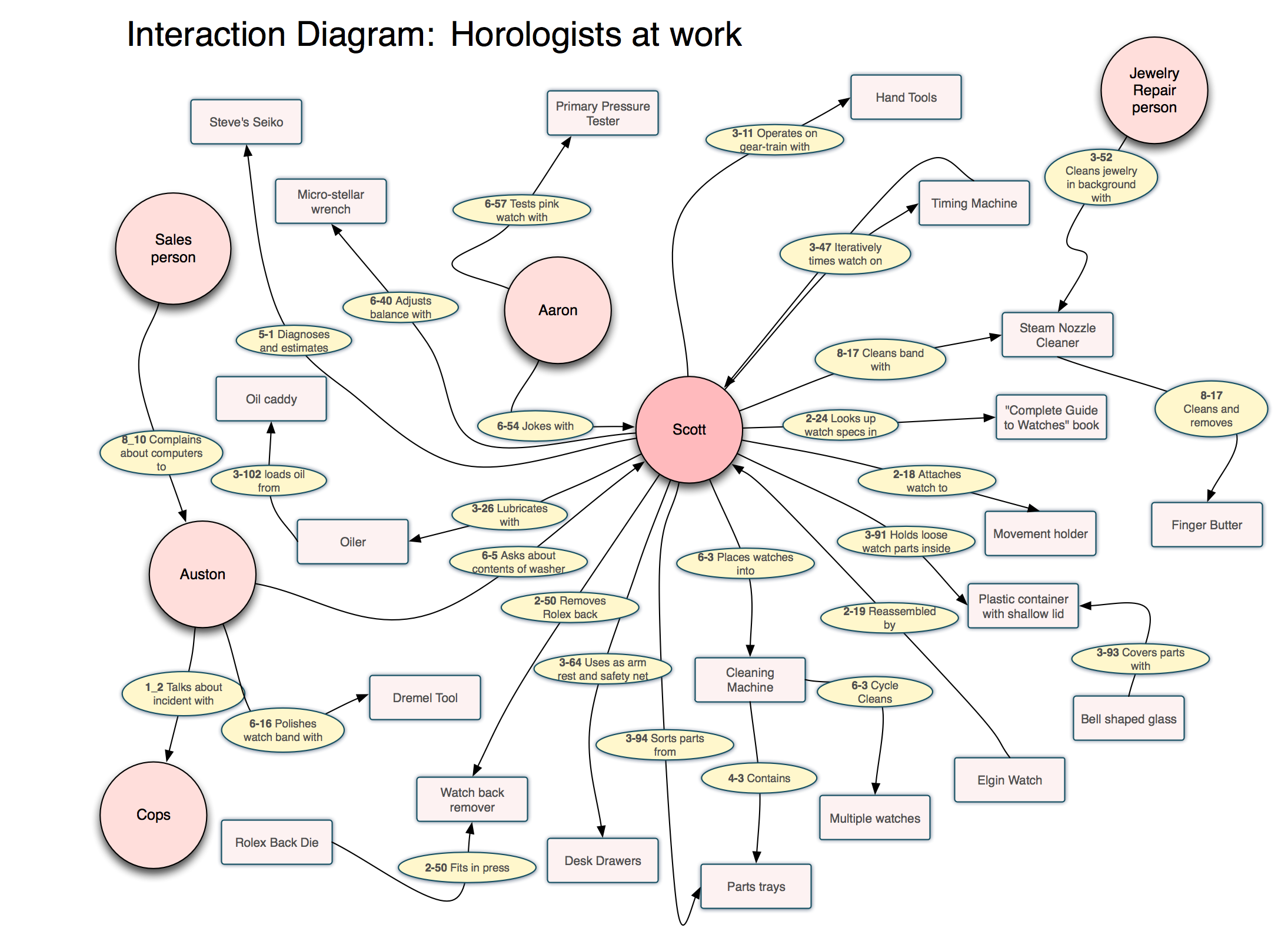

The diagram below is intended to capture the interactions between the horologists and their environment. The numbered codes in the yellow ovals tie the relationships back to lines in the transcript. The transcript was created from raw video footage taken over 3 hours observing the horologists and is the basis of most of the following assignments.

Begin Transcript

This interview is primarily with Scott the horologist but also includes interactions with horologists Auston and Aaron. The interview took place over a 3 hour period on a Monday afternoon. The transcript includes several stills from the video.

Jump to Segment: 1 2 3 4 5 6 7 81-1 [ I show up and sit with Scott. We introduce ourselves and begin talking. Scott is wearing a watch on both wrists, he explains they are customer watches and he is wearing these to test the automatic winding mechanisms while he works. His work area in front of him is called the bench ]

1-2 [ Cops are in the lobby. Talking with owner ]

1-3 [ Scott works on 1902 Elgin watch movement. Reassembling it after cleaning ]

1-4 [Steve] How many years have you been an Horologist? [Scott] 21 Years

1-5 [Steve] Did you go to school for it?

1-6 [Scott] 2 years, at a school in Plainwell Michigan

1-7 [Steve] There's a certification?

1-8 [Scott] At the time there wasn't, no, but I'm getting ready to take one

1-9 [Scott] American watch and clock makers institute, They've created a certification called CW21, which is certified watchmaker for the 21st century. They updated it because a lot of stuff has happened in the last century from mechanical watches, to electronic watches to quartz watches so there's a lot of new information they didn't really have a program for, but now they do.

1-10 : [Steve] Do most of the watchmakers you work with have certifications or are they journey people?

1-11 [Scott] I think all of us have some form of certification or schooling except for Jorge, who learned from his father, but he's been working on watches for 57 years

1-12 - [Steve] What makes you unique as a watch technician, what's the difference, what sets you apart?

1-13 [Aaron] There are only 15,000 of us

1-14 [Scott] Some number like that, when I started there were about 20k of us. Their avg age was like 58. When I finished there were about 15k and there avg age was 65. What happened is in the war, there were a lot of mechanical things that needed to be worked on for the service, so there were a lot of watchmakers in their 80's

2-1 [Steve] What types of watches do you mainly work on?

2-2 [Scott] Mainly American. There were a lot more American watches in Michigan, we lived in Flint everyone wanted to buy American. So a lot of the stuff we got was presentation stuff presented to old General Motors employees, which was a lot of old American stuff. but now there are no American companies left.

2-3 [Steve] there are no more American mechanical watch brands?

2-4 [Scott] mmm, none that I know, there are a couple of very small businesses, watchmakers that specifically make brands but I don't know what they are off the top of my head. None of the big companies are left that are American made.

2-5 [Steve] What do people assume about you when you tell them you are a watchmaker. Is there an uninformed stereotype?

2-6 [Scott] "Wow, you're young" -- and I'm 40! [laughs]

2-7 [Scott] Yeah, I'm awfully young to be a watchmaker. I would say the stereotypical watchmaker is an old guy.

2-8 [Steve] Then what are the accurate stereotypes of horologists? Of all the watchmakers you know what does everyone seem to have in common?

2-9 [Scott] You know, I really don't know. I would say that they're quirky. They each have their own individualism, some are reserved, and some people think that - "who can sit there and look at something that small for 8 hours per day?". So people say "all of thos watchmakers I know are kind of quirky. They're all different."

2-10 [Scott] What other profession is most similar to watchmaking?

2-11 [Scott] We were talking about this today. Gunsmith, maybe? Working on gyroscopic systems. There's a lot of micromechanical work.

2-12 [Steve] So micromechanical is the correct term for that kind of system?

2-13 [Scott] Yeah, in fact when I went to school there were several guys who went right from watchmaker school to fixing indicators and micromechanics. We learned to use lathes and cut teeth and learned about metals and how they react to heat and how to harden them and to soften them and how to cut them. How the steel can be worked, whether tool steel or steel for other applications. That can go for anything, when working on devices where you need to know the properties and how the metal reacts. Take this main spring right here (lifts a watch main spring, a long strip of steel with burnished look)

See how it brownish blue color - that's spring steel - if it was more of a straw color it would be hardened steel. This one, see how blue it is - that's a different type of spring.

2-14 [Scott] You have to know the properties of steel because each part plays a different part. Can it take a polish - if something is really soft it won't take a polish as well as something harder. Now they have a lot of new metals, alloys that aren't carbon steel. These break, too - that came out of a Rolex [holding a whitish metal spring]

2-15 [Steve] My focus in this interview is mainly on what you are doing right now, the actual repair of watches. What's the most common service you do for watches?

2-16 [Scott] Probably an overhaul on Mechanical watches - where you completely disassemble it, clean it to take all the old oil and dirt off of it, replace all the parts that need replacing, then you reassemble it and lubricate it as you're reassembling

2-17 [Steve] What type of watch is this you are working on?

2-18 [ Pan to Work area, Scott has a watch body attached to a watch movement holder, looks like a small jig with thumbscrews to hold the movement in place while he works ]

2-19 [Scott] This is an old Elgin pocketwatch. This is a pretty old one, I would say it's probably the turn of the century

2-20 [Scott] You can look it up in that book right there

2-21 [ Points to a thick book with watches on the cover, paperback, pretty well worn. "The complete price guide to watches" ]

2-22 [Steve] Is this the bible of the hobby?

2-23 [Scott] Naaa, that has a lot of info about values, what the values are, but it doesn't give you much technical information. You can find out what a lot of the movements are but nothing depth.

2-24 [ Looks in the book ]

2-25 [Scott] That's a 9 million serial number, so according to the book it's about 1902. This is a bible for prices I'd say - there are quartz watches through pre-1850 - it's just a guide - there are a lot of things that aren't in it but there are a whole lot of things that are.

2-26 [Scott] I've got to get up and switch stuff in that machine over there - I'll show you this real quick if you want to

2-27 [ Gets up from work bench, leaves watch there. Walks over to wall at rear of room which has multiple machines on it ]

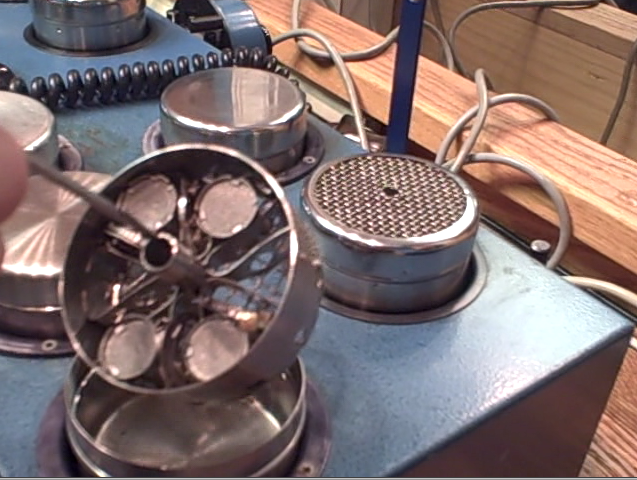

2-28 [Scott] This is the cleaning machine that has one cleaning and 3 rinses. This is an ultrasonic machine, it actually vibrates at ultrasonic frequencies and takes all of the old oil and stuff off the parts

2-29 [ He lifts a tray out of a well of liquid. It has dividers in it with very small part in each divider, the fluid drains out through holes in the bottom ]

2-30 [Steve] So these are all the parts of the watches?

2-31 [Scott] There's 4 movements in here. Not the cases. You see there's 4 baskets - those are all the parts and the rest are the plates, the larger parts that won't fit in the baskets.

2-32 [ Moves it all to another section of the machine]

2-33 [Scott] Then this blows, blows heat on it to evaporate the cleaner off of it

2-34 [Steve] The cleaner is water based?

2-35 [Scott] No, it's benzene and they usually spend 15 min on each cycle. It usually takes about an hour of switching the parts out. First you go in the cleaner and then you rinse the cleaner off in this solution and then goes in an ultrasonic rinse, then the drying happens - so 15,15,15,15.

2-36 [Steve] so during the day you and the other watchmakers walk over to this machine and change out watches and parts?

2-37 [ Voice over the intercom asking about watch progress ]

2-38 [Scott] We've talked about getting a new type of machine which does all of this in one step, all 4 steps in one so we don't have to get up and switch it out. This is an older model, but for its time it was very updated but they haven't changed the technology other than auto-changing.

2-39 [ Moves to machine directory to the right with oscilloscope readout and cradle]

2-40 [Scott] This machine actually times out the watch. It'll tell you if you have a mechanical watch and this can tell you if it's running fast or slow and I'll show you that in a bit. It can also tell you if it's in beat.

2-41 [ Moves to the right to a machine that looks like a small breadmaker ]

2-42 [Scott] And this is a pressure tester. It can tell you whether or not the watch is water resistant. It measures the crystal, it builds up pressure and this will tell you if the crystal is flexing. It measures the reflection in the crystal, it holds the pressure and as time passes the crystal will flex back up and demonstrate a change in pressure. If it's a water resistant watch we do this test as a part of an overhaul.

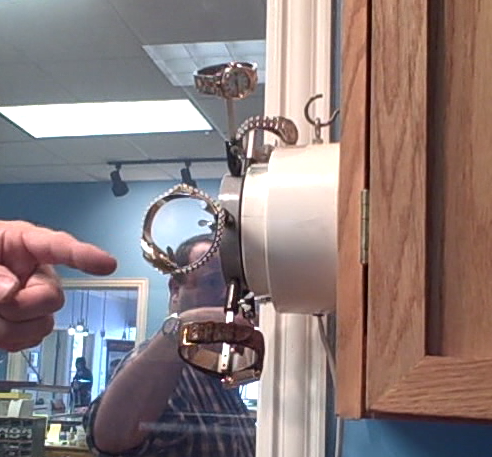

2-43 [ points to a round machine attached to the side of the cabinet, it has several 10" arms radiating like spokes with nice watches at the end of each arm. It spins in circles simulating movement for the autowinders ]

2-44 [Scott] All of these that are Rolexes, all of them are water resistant so they all go through the pressure tester.

2-45 [ Shows me a second pressure tester that looks like a coffee presspot with a cranks and 5 bar pressure gauge ]

2-46 [Scott] This is the old style pressure tester - what I use it for mostly for is watches that fail the closed pressure tester. It's hard to tell where they might be leaking. might be in the crown or places around the crystal or case back. So if you can't tell where it's leaking - so you actually put it in here an tighten down the seals and then pump up pressure - once you get the pressure up you let it sit in this machine for a while what that allows it to do is build up pressure inside the watch

2-47 [Scott] Then we dip it in the water and release the pressure - escaping air will show you where the leak was. It helps me troubleshoot difficult problems.

2-48 [ Tells me anecdote about Rolexes ]

2-49 - [Scott] Have you ever seen an old Rolex?

2-50 [shows me the back of a Rolex, has a toothed gripping edge along the back of the case. Holds up a socket that matches]

2-51 [Scott] This has teeth on it that actually grab it so you can put it in this machine with the proper die and you can unscrew the back. Some people don't have this tool - so they'll actually drill 2 small holes and use those to grab the back and rotate it.

2-52 [Scott] Well they filled in the holes - I couldn't figure out why it was leaking. They filled with solder but what happened was there were minute holes in the solder. I'd never seen anything like it- it was leaking right out the middle of the metal and I'm like "What in the heck?". So.

2-53 [Steve] So you come across a lot of bad fixes by other watchmakers, like a car mechanic working on an old car?

2-54 [Scott] Sometimes, yes.

3-1 [Steve] So the job you are doing right now. A customer dropped this off, what state was it in?

3-2 [Scott] This was actually in pretty good shape. It was an old watch that hadn't been serviced in a while. So the oils had dried up so it just wasn't running properly. I disassembled it and I'm in the middle of the process of reassembling it. Once I've reassembled it I can diagnose if it has any other problems but until you get it running right there's no way to tell.

3-3 [Scott] This is really the brains of the whole watch [ Explains the principle of the balance wheel and the weighted screws around the perimeter ] If it's not balanced the watch will run different in different positions.

3-4 [Scott] [ Explains stem positions for pocket watches ] People almost always have the stem up, left, or right based on the way that they rest it in their pockets.

3-5 [Scott] I've seen all kinds of ways of doing this but the relationship between the weight of this wheel and the tension of this hair spring tells how fast the watch will be running. Here is where this back and forth motion is converted into a round-and-round motion.

3-6 [ Scott Shows me how the balance wheel and hairspring mount in the movement ]

3-7 [Scott] This is the mainspring here- the power all comes from there. All this balance wheel does is govern how slow or fast that this gear train runs down.

3-8 [ Gets ready to put it back together ]

3-9 [ Picks up eyeloop and fixes it over eye without using straps ]

3-10 [Scott] I'm aligning what's called the pallet fork, what changes the back and forth motion to round and round. It has an arbor on it and it's sometimes hard to line up

3-11 [ Takes about 30 seconds, uses tweezers and two different screwdriver tools. ]

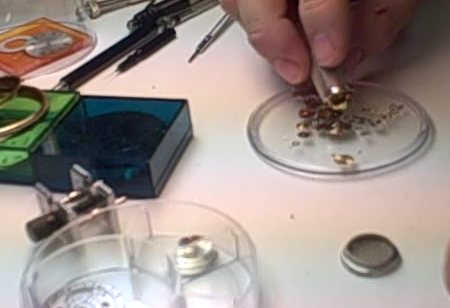

3-12 [ He has a small pile of screws and gears he is pulling parts from ]

3-13 [Scott] Now there are several diff sizes of screws, so if you don't have a lot of screws it's hard to know which screw goes where. So you just kind of have to figure it out.

3-14 [Steve] Do you have to feel if they are right or do you end up corssthreading stuff a lot?

3-15 - [Scott] Umm, a lot of it is that you can actually look at them, I just use 3x power, but you can actually look at them and tell that they won't fit in the hole after a while

3-16 [ Cranking with small screwdriver ]

3-17 - [Scott] Now I'm just going to wind up the mainspring to see how ... OK I'm going to have to get the rest of the case. Walks over and grabs the rest of the case from nearby.

3-18 [Steve] Do you use the same tools on every watch, the same basic kit?

3-19 [Scott] Yeah, basically. Sometimes we have to make our own tools

3-20 [ Conversation amongst the watchmakers about the best tools, they say Swiss and German tools are best but a lot of time they have to make their own. ]

3-21 [ Scott quickly slips the Elgin movement into the case and attaches the crown, begins winding it, removes it from the case again and sets it in his work jig ]

3-22 [Scott] The problem with watchmakers tools is that most of the people that make them are not watchmakers. So they make something they saw in a book somewhere and they decide they can make it cheaper.

3-23 [ We talk about quality issues with Chinese tools. Talk about the over-pricing of European tools ]

3-24 [ Owner walks over, introduces himself as Auston Curry. Watchmakers make Steve Austin Bionic Man jokes. I explain why I chose watchmakers ]

3-25 [ Scott finishes reassembling the watch ]

3-26 [Scott] Now what I'm doing is this is an automatic oiler - and this actually has a plunger that puts oil onto the points when you put it down - so now I'm oiling the train, lubricating the places where there is friction.

3-27 [Steve] Is there a bearing surface?

3-28 [Scott] Yes, this is a 15 jewel movement. This means there are 15 bearing surfaces that have a hardened jewel in it. They're usually in pairs - it's actually a synthetic corundum which is a sapphire or ruby. On this watch the centerwheel is not jeweled - on most watches that are considered 17 jewel watches this centerwheel is jeweled.

3-29 [Scott] The way you count jewels, usually [ Explains the jewel locations throughout the movement of the Elgin ]

3-30 [ Aaron at the next desk is using a punch on another watch ]

3-31 [Steve] So this entire chunk of moving parts is called the movement?

3-32 [Scott] Yes. And these parts are the case of the watch - which consists of the case [ outer ring structure of watch ], and the case back that covers the back of the movement [ flat piece for back of watch ], and this is the bezel [parts that holds the crystal in ]. This came in with a broken crystal so we need to replace the crystal

3-33 [Steve] Where do you get a replacement crystal. Is that a common size or do you have to do custom work?

3-34 [Scott] We can get acrylic ones of just about any size but we have some parts down here. We have some glass ones in the bottom drawer ... We have parts everywhere.

3-35 [ At this point Scott shows me the organization of the office extra parts which are stored in places all over the office in some cool old storage systems. They have parts from all over the place, very cool. Lots of New Old Stock and great labeling systems. Quarts movements, springs, gaskets, everything they need. ]

3-36 [ Shows me a mainspring, describes how it needs to be coiled into a very small shape to fit into the barrel of a watch ]

3-37 [Scott] We buy old watch movements and we sort them by makers - parts are getting really hard to find for old watches so we keep these around. We usually buy them off the street for parts.

3-38 [Steve] So if something was failed int his old Elgin you would likely have the parts on hand to fix it?

3-39 [Scott] You can still order most of those but we have a machine we can hand cut custom ones if we need to. [ Scott is interrupted and asked about a watch, looking for a particular customer's watch but not sure what name it is under. Filing system seems to be all paper based. ]

3-40 [Scott] We do buy old pocket watches [walks to cabinet and shows me a whole bunch of pocket watch carcasses ] We buy them for parts. Elgin is one of the largest producers of pocket watches so we would probably have a part for that.

3-41 [Steve] If I wasn't standing here talking with you how long would it take for you to reassemble this watch? How long do you allow?

3-42 [Scott] We don't really allow a certain length of time because we're always up looking for jobs or waiting on customers or giving estimates or doing battery replacement.

3-43 [Scott] If I were to sit down, aside from the hour in the cleaner, it would probably take me 15 min to tear it apart, then probably 30 minutes to put it back together. But then you have to look for a crystal, and then you have to polish the case, and - every watch is a different story.

3-44 [Scott] That's why I have to estimate it. I have to figure out how much in parts it will take and how long to work on it

3-45 [Aaron] It also depends on if the person is a tinkerer or not

3-46 [Scott] Yeah - if somebody has actually got into it and messed it up. Every single job is different. We can put this on the timing machine if you'd like.

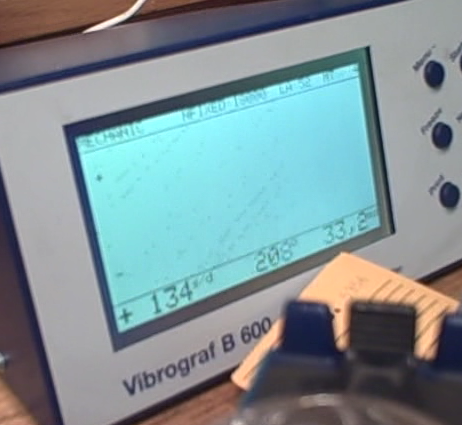

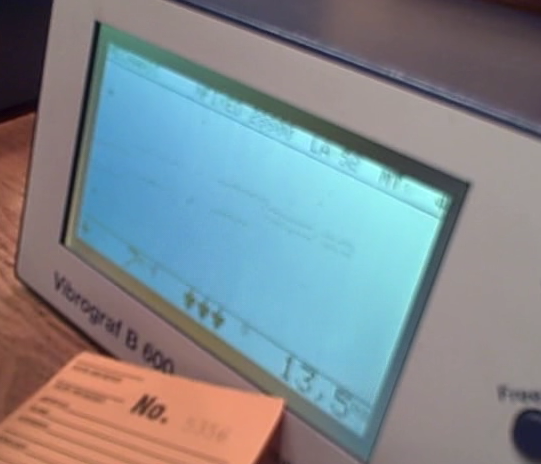

3-47 [ We carry the watch body to the timing machine with the oscilloscope face ]

3-48 [Scott] This isn't quite fully assembled, I still haven't attached the dial parts, dial wheel and the hands.

3-49 [ Scott rests the watch in the cradle of the timing machine]

3-50 [He hooks up the leads and the watch is immediately audible ]

3-51 [Scott] This is where we find out how much it needs to be adjusted.

3-52 [ Having a hard time picking up the signal - screen says 'searching'. From adjacent room we hear steam jets from jewelry people cleaning off their work ]

3-53 [ Scott takes the watch back to his desk and shows me the watch dial parts, how the hour and minute hands stack on top of the hour wheel and how the seconds hand works on this old watch, offset called 'Small seconds'. ]

3-54 [ We talk about the case and the dial of the watch. Old pocket watches were often sold separately. People would likely swap parts over the years. ]

3-55 [Scott] Now what I'm doing is looking to make sure that the hairspring is perfectly flat. I didn't do that before I took it over to the timer. Now I'm just looking at it, making sure it's not touching anything.

3-56 [Steve] So most of the day you have on your eyeloop? Are you holding that in place with your face muscles?

3-57 [Scott] Yes! [ We talk more about that ]

3-58 [Scott] That's interesting because all 4 of us watchmakers use different ways of holding out optical pieces on our eyes.

3-59 [ Aaron walks up and pulls his off. There is a long steel strap preformed in a semi circle - he can wrap this around the back of his head and it helps keep his eyeloop on ]

3-60 [Aaron] I made this - it's from an old windshield wiper.

3-61 [Scott] We make a lot of our own tools. Auston has a set of frames he repurposed to hold his eyeloop and Jorge has his attached to his glasses. When I first started working I worked with an old guy who did this and I used to use a spring but I didn't like it. [Jokes] It messed up my hair but now I don't have much hair, so...

3-62 [ Auston at another desk working on another watch ]

3-63 [Steve] You are in a hunched over position all day doing fine motor movements. Does that screw with your back - do you have any ergonomic issues?

3-64 [Scott] I haven't yet but maybe since you brought it up now maybe I will. Thanks! Usually I sit a little lower - not sure if you've noticed but I pull out my drawers a lot and I rest my arms here [ shows me ]

3-65 [Scott] This also helps because sometimes parts get away from you and probably 80% of the time they will fall in here. And 20% of the time I push them in and lose them

3-66 [Aaron] And when it's gone it's just gone!

3-67 [Scott] There's an old joke about watchmakers and it says "I have 20 years of experience, 15 at the bench and 5 on the floor".

3-68 [Steve] So your work area here, you have this white matt and several projects going on at once.

3-69 [Scott] 5, 4 in the cleaner and this one. And these -

3-67 [ Scott is wearing a watch on both wrists, a Tissot and an Omega, he explains they are customer watches and he is wearing these to test the automatic winding mechanisms while he works. ]

3-68 [Scott] Sometimes the autowinder doesn't correctly simulate the movements of an arm so I do this to check them.

3-69 [ After checking the Elgin over again Scott returns it to the timer ]

3-70 [Steve] What adjustments did you make?

3-71 - I adjusted the height of the hairspring

3-72 [ It's now picking up a signal on the screen. It's drawing 2 lines across the screen in a very loose scatterplot ]

3-73 [Scott] We're at least picking up something. [he turns knobs ] This has a lot of extra noise. See the double line [two lines, far apart]? Ideally you would get a straight line - the reason it has a double line is that hairspring that has a jewel that's supposed to center that balance wheel, it's not returning to center. If it was exactly centered in the perfect world that would be a straight line

3-74 [Scott] There's a lot of other things that can affect it. Like over the years people can move the two jewels on the pallet fork which will change that so even if it's in the direct center you'll get an offset. This seems to be running 30 seconds fast per day. These are ghost readings from lots of noise in the watch - most likely not from manufacturing but improper repair in the past.

3-75 [Scott] It seems to be keeping a pretty straight line so I'm going to just slow it down a bit. The hair spring - the length of that determines, in conjunction with many other things, how fast the watch runs. To speed it up you would shorten the length of the hairspring and to slow it down you would lengthen it.

3-76 [Scott] Almost all watches have what's called a regulator and it has 2 pins that go on the edge of the hairspring that you can use to lengthen or shorten the length of that spring. [ points out markings ] Fast and slow - this lever moves one way to slow, one way to speed it up. This has a threaded microregulator that holds the end of the spring [ turns threaded shaft - like a brake drum adjustment]

3-77 [Steve] How did they do this kind of manufacturing in 1902?

3-78 [Scott] They were amazing back then!

3-79 [Scott] [ We walk back over to the timing machine and set the elgin back in the cradle ] this one is now pretty close to an adjustments. If you can get some of these old ones within +/- 30 seconds per day they are doing pretty good. This one will probably do better than that.

3-80 [Steve] so you've disassembled the watch, cleaned it, reassembled it most of the way, set the timing - is it time to reassemble?

3-81 [Scott] Yep. We'll reassemble it then let it run through a full wind top to bottom - because from the high end of motion when the main spring is all the way wound up and has the most strength the watch is actually going to rotate farther than when it's wound down. So we want to watch it to make sure that it's going to run the same through the whole wind of the watch.

3-82 [Steve] So we will reassemble?

3-83 [Scott] We can. We're going to have to look for a crystal unless you want me to get those other ones out and look at them

3-84 [ Now scott is setting aside the Elgin pieces in a small blue box on his counter, carefully setting each screw and component in with his tweezers ]

3-85 [ Scott walks over to the cleaner, he lifts the tray out from earlier - it has 4 watches in it. ]

3-86 [Scott] 2 of these are Rolexes. Ones an old military watch and one is actually a quartz watch.

3-87 [ I ask scott about his workspace ] [Steve] The tools are always over here? [ on the right ].

3-88 [Scott] Yes, Because I'm right handed.

3-89 [Steve] Why do you have these glasses [ water glasses ] over the watch parts?

3-90 [Scott] I like to keep the parts here - this is a Rolex dial - but I don't like dust getting on these parts. [ Scott points to a series of small colored plastic square containers on his desk with disassembled watches in them ] I use these covers to keep the dust off.

3-91 [Scott] [ Scott uses the containers upside down, the parts rest in the shallow lid while the deep part of the container sits on top - like a cake platter with a top ] I use the lid as the base because it's easier to reach in and get the parts, whereas if I was using it the intended way I would have to reach over the side walls to find parts and pull them out.

3-92 [Steve] Are these made for watchmakers?

3-93 [Scott] No. You can get them at the Container Store. I make a lot of my own tools or modify existing stuff. [ Pulls out a plastic case with a lid ] This is one that they actually make for the purpose [ much bigger ] I even use this wrong, using the shallow lid as a work area. [ He sets a bellshaped margarita glass with a busted stem upside down over the container ] I use this bell shaped glass as a cover, too.

3-94 [ Starts to sort out parts from the drying tray, Pulls out the backing plate for the movement of a Rolex. It has very cool machine surface marks, beautiful. He pulls out plates, weights, gears, screws and stages them into a couple of different plastic trays in front of him ]

3-95 [Steve] Are you sorting the watch parts into these different trays?

3-96 [Scott] No, these are all part of the same watch [ Moves the rest of the drying tray to the side, sets the bell shaped glass on top of it to protect it. ] These are the autowind system and it's opposite plate. [ Scott shows me all of the parts and gives a brief explanation of everything ]

3-97 [ The tiniest screws and gears were all resting in a thimble-sized container so they would not get lost. He upturns this into his plastic parts tray.]

3-98 [Steve] Oh my god. That's insane.

3-99 [Scott] Oh yeah, this one needs a mainspring, too. The failed one I showed you earlier came out of this watch. [ He starts showing me the jewels, each about the size of a flea ] This is the hole jewel and this is its mate the cap jewel, they go together like this - [ One has a divot in it, the other rests in the divot like a mortar and pestle ] They go together like this with a little dot of oil goes between the two.

3-100 [ looking around the parts ] Trying to sort the parts out but I can't find one of the jewels. In that case I'll just start to put things together and it will show up later, probably.

3-101 [ Starts to reassemble ]

3-102 [Sets the movement in the movement holder, it's like a small bench vise that allows him to rest the backing plate flat.

3- Starts lubricating the jewels that do not leave the backing plate during disassembly. Uses auto-oiler - a tool that allows him to apply oil to very small points.

3- He shows me his lubrication options, 4 small pots with lids on plate - sort of like a painter's palette - each lube has different applications.

3- When the auto-oiler is not needed he temporarily sets it in what looks like an appropriated fountain pen base

3- He now alternates between tweezers and auto-oiler picking up plates and setting oil in jewel recesses

3- Sometimes he has to push oil down in the holes

3- Begins assembling minute pieces

3- Sorts the screws out, because there are so many of them]

3-103 [Steve] So from watch to watch there are differences. How confusing is that?

3-104 [Scott] When I started it was real confusing. Anymore I can tell you right now these are the plate jewels [ names off all the parts by sight ] These screws with a blue head hold on the date system on a Rolex.

3-105 [Scott] [He's not using his eyeloop right now and he comments saying he is supposed to be, like he is breaking a rule ]

3-106 [Steve] How often do you totally lose stuff?

3-107 [Scott] Daily.

3-108 [Steve] Is that your most frequent mistake, to lose something?

3-109 [Scott] Yeah, I'd have to say [ Checks with Aaron ] Yeah, that's the most frequent mistake.

3-110 [Steve] What's the second most frequent?

3-111 [Scott] Coming to work [ we laugh ] Monday!

3-112 [ Aaron stops and tells me about the worst time he ever lost something. A main spring launched out of the piece he was working on and he looked for it forever, found it stuck in the ceiling ]

3-113 [ Scott continues assembling ]

3-114 [ Scott tells me about the floors they just had put in. They are hardwood and he says it's nice because when you drop things you can hear them hit. Coincidence that it works so well ]

3-115 [Scott] OK, I need to find a mainspring. I'll show you this over here [ walks over to hutch near entrance, opens drawer and grabs a box ] These are sold to us by Rolex. [ Digs for a while, can't find one. Takes approx 3 minutes to find. ] These are marked, so not too hard to find.

3-116 [Scott] Rolex is probably the most common watch that we work on here. The most common Quartz watch we work on is Tag.

3-117 [Scott] This is actually a different kind of lubricant for the inside of the barrel

3-118 [ Scott shows me how the mainspring is situated in the barrell and slips along the inside of the main spring when at full wind - this is how you can't overwind a watch. He demonstrates how the main spring is stiffer on the outermost coil facilitate keeping the spring in place ]

1 - [ Empty, Placeholder for document]

5-1 [Scott takes a break to disassemble my broken Seiko, this is how he does diagnostics ]

5-2 [ Scott unscrews the back of my watch to examine the autowind mechanism, mine has been losing its wind after 2-3 hours. ]

5-3 [ Phone rings, conversations in the office ]

5-4 [ Scott spends about 2 minutes looking at it ]

6-1 [Scott] [ Looking at my Seiko ] This watch hasn't been serviced in a while. One of the main ways you can tell is that, remember how we talked about the jewels - you see the oil is dried up in there and you can see it. That is a sign that it needs to be serviced. [ Starts to turn it around and shows that the autowinder isn't moving like it should ] See how it's getting stuck? That's part of it.

6-2 [Scott] At first when I was looking at it I thought maybe one of these screws was not screwed down tight - that mayeb that's why it was stopping.

6-3 [ Owner stops by and asks him if he has watches in the cleaner. He says he has 2 Rolexes in there and another one. I just put em in there about half an hour ago ]

6-4 [Scott] Anyways, that's probably all because the lubrication has dried up. That should be much smoother than it is.

6-5 [ Owner, Auston stops to talk about all of the Rolexes in the washer. Scott shows him serial numbers on all of the work tickets ]

6-6 [Steve] So is that how you keep track of the watches?

6-7 [Scott] Yeah [shows me work ticket ] We usually use the model numbers and serial numbers and a description of the dial and if you look we even have a stamp. We say how many links are in each case so we don't get the bands mixed up. This tells where its at on the buckle so when the customer comes in this is the adjustment - so that when they come in and put it on it fits like it did when they dropped it off. Because we take the bands all apart, clean them and refinish them - this lets is know all about the watch that we can, just so we don't get mixed up.

6-8 [Steve] So this all goes in a computer?

6-9 [Scott] No, it's all hard-filed

6-10 [Scott] Well, it's worked forever like that.

6-11 [Scott] We do business with some out of state customers, they ship them in from say, Tennessee, when they ship them if they get lost or stolen we have the model and serial numbers on hand.

6-12 [Steve] Do you check watches you receive to see whether or not they are stolen?

6-14 [Scott] No, never really thought of doing that. But that's a good question. There are sites you can go on to see if a Rolex is stolen.

6-15 [Auston] Rolex and the insurance company keep a database. But we don't look for it normally. The police send us updates when one is stolen and we'll keep an eye out for it. We do make sure before we buy them, though. We operate under laws very similar to pawn shops.

6-16 [ Auston is using a dremel tool with an abrasive on the end cleaning up a fancy watchband ]

6-17 [ Auston tells me a story about a client who lost their ring.The guy who found it came in asking what it was worth. They called the cops - that's why they were in the lobby . ]

6-18 [ Walk back over to Scott's bench. He is back working on the Rolex. Finishing up with the Barrel ]

6-19 [Scott] So that big long mainspring all fit in there. [ Scott switched between screwdriver and tweezers and autooiler ] Sometimes I forget how I want to put them together [ Sorting through parts ] [Watch still on stand ]

6-20 [Steve] So meticulous

6-22 [Scott] My dad was in construction. So I always thought this was like construction. You learn to swing a hammer and after you've bent a few nails you've learned how to drive a nail. But after being in the business a long time and seeing guys come and go it's not that way. It takes a special ... knack ... to be able to do it. [ I ask a question] Hmmm, not so much attention span... well maybe it is attention span .... Not everybody can do it is my point.

6-23 [ Intercom comes over, asks Auston some questionsabout engraved bands]

6-24 [ Lines up all the gear train jewels and pivots ]

6-25 [Scott] [ Sets upper jewels into place ] These upper cap jewels are really hard to set, because it wants to tip and it doesn't want to fall in the hole .

6-26 [Scott] The other ones went in fine. This is the barrel bridge - [ goes on to show me more detailed working ]

6-27 [Scott] [ Lubricating all train gears in the watch ] Lubricating has to be inside the oil cup - if you get it outside of the oil cup it will flow - if you get it beyond this ridge it will draw the oil right out by capillary action. If oil gets on the hairspring it will cause it to stick, which will make the watch run fast.

6-28 [ Tells me about the effects of magnetism on older watches. Sometimes he has to use a demagnetizer. Tells me some anecdotes. Returns to watch ]

6-29 [Scott] Don't know if you can see this but this acually ratchets[ using screwdriver to slightly wind the watch ] You can wind this forever and it will just slip around the barrell. [ He has partially assembled without the jewels, shows the watch running and says it will be much smoother when the jewels are in ]

6-30 [Scott] Jewels are only interchangeable within this model, sometimes within brands

6-31 [ Using tweezers he sets a jewel inside it's companion jewel. Shows me a technique to oil them in place ]

6-32 [Scott] Once the oil is down in there it will hold them together

6-33 [Scott] The other way is to put the oil in there and then put it together [Shows me]

6-34 [ Aaron and another employee talk about a new watch next to us ]

6-35 [Scott] Sometimes you can take 4 or 5 minutes trying to oil one of those properly. If you look at this real close through the loop. [ I look through the loop, see the correct way to oil the jewels, a circle in the center of the cap jewel ]

6-36 [Steve] Are you guys busy?

6-37 [Scott] We're not busy right now. There's nobody in the lobby.

6-38 [ We walk over and set the watch on the timing machine ] See how we have 2 lines? [ much different from the elgin ] There's an adjustment to get those lines closer together [ he adjusts it and the lines come closer together ] Now what we're doing is turning where that's hooked to the end of the hairspring which means that that jewel will be closer to center. [ Moves it tp perfect single line ]

6-39 [Scott] That's called "in-beat". You can now see it's running 7-9 seconds per day fast. We watch and make sure that's consistent. [ Waits, Picks it up, moves it over to his bench, pulls out a crazy looking tool ] This is the micro-stellar wrench. It has increments so you can know how much you've turned it, so you can do the same thing to both sides on the screws for the balance wheel. You adjust the weight of the balance wheel you change the outer weight of the balance.

6-40 [ Makes 2 minutes of adjustments, evenly turning each side. Shows me Rolex stop mechanism ]

6-41 [ Sets the Rolex back on the timing machine. He adjusted it 4 marks and the adjustment has gone from 7 seconds fast to 4 seconds fast. He's going to move a few more marks, moves it back to his bench. He says he has to do this several times befire getting it right. ]

6-42 [ Conversations giving estimate to another store employee]

6-43 [Scott] This is a certified chronometer from Rolex, it has a tolerance of +6 minutes per month or - 4 minutes per month. We usually strive for something much better than that

6-44 [ Returns to the timer. It shows +/-0 seconds per day so should be really good ]

6-45 [Scott] I usually set it right at zero, but it's better to be a little fast than a little slow.

6-46 [Steve] why's that?

6-47 [Scott] Most people would rather be early than late

6-48 [ gets to +- 0 seconds ]

6-49 [Scott] If you look at this- this tells you how many degrees of motion the balance is swinging, it should be 270 or above and this shows 302. This shows that we have a good flow through the whole train, the lubrication is good. There are a lot of tests this will run.

6-50 [Scott] I'm going to call this good and see how it runs on a winding machine. So now it's just a matter of putting the mechanism back together with the autowind system. Unless there are big troubles, repairing the movement is the main technical part of repairing the watch.

6-51 [Steve] How many of these do you get done per day?

6-52 [Scott] One if I'm lucky. Usually we're doing batteries, we have to order parts from the factories, I called Omega, Gucci, IWC today. A wholesaler, I mean this isn't all my job - we do estimates on watches.

6-53 [Aaron joins conversation ]

6-54 [Scott] The other room over there is jewelry. But we do our own cases. Aaron is excellent at refinishing cases, he's really, really good at it. [ Jokes about making him do the case work ]

6-55 [Scott] We use more jewelry related tools to do that work.

6-56 [ Explains reverser-wheel autowind system as he assembles it ]

6-57 [ Aaron looks at a pink watch a lady brought in for battery changes. He immediately goes to test the water tightness of the watch before opening it. ]

6-58 [ Scott explains that they do that so that people can't claim the watch lost water resistance as a result of the repair. If it's not initially resistant they will mark it down in their records as policy ]

6-59 The thing is that some times customers don't remember and we can't remember with all he watches we do every day so the record keeping helps - we write in the back of the watch with a marker.

6-60 [ Starts telling me about watchmaker marks, shows me the backing plate for the old Elgin. We see individual marks scratched in from the 30's, 50's 70's from horologists who have serviced the watch ]

6-61 [Steve] It's like a grafitti tag?

6-62 [Scott] [laughs ] yes - it's most useful if you get the watch again. To see that you had worked on it before, help you remember it. This one has a lot of marks - someone took care of this watch. Today we use ink, because scratches could be considered damage to a high grade watch.

6-63 [ Conversing with Auston - Starts talking about a customer who came in with a chipped dial and got mad when they fixed it ue to sentimental value. And she waited a year to tell us. ]

6-64 [Auston] Customers are something. [ Talks about how he manages customer service]

6-65 [ Scott gets a test message, sets down his tools and answers it ]

6-66 [Steve] how many watch shops around town like this one?

6-67 - [Scott] none like this. We are pretty big. There's not that many people doing it any more. I think we have the most watchmakers of just about anyone in Texas. There are only 15k watchmakers in the whole country

6-68 [ Auston gets a phone call over the intercom, stops to answer it. Getting close to closing so guys are starting to get restless. ]

6-69 [Scott] I lost a screw, but just found it. Here is the face for the Rolex.

6-70 [Scott] This is really unsual, this would be nice to collect. [ Tells me about faces, the old Elgin face is copper with a ceramic glaze ]

6-71 : [Steve] How many watches do you own?

[Scott] I don't know. Laughs [ tells me anecdote about buying a box of watches ]

6-72 [ Assembling the dial side and date system - dial side vs/ plate side of movements. Use different oils ]

6-73 [ The setting parts also take a different type ]

7-1 [ Discussion about values of watches ]

7-2 [Scott] It's a very precise machine. It has value, it actually has value.

7-3 [ Discussion about repair of watches compared to cars ]

7-4 [Scott] It's a quality piece of machinery

7-5 [ They sit on ebay every day, watching watches ]

[Aaron] Looking through an eyeloop all day you really notice how filthy things are.

7-6 [Scott] [ laughs ]

7-7 [ We talk about nasty things they've seen. hair in watches sounds gross ]

8-1 - [Scott] The Rolex has an instant change data so we roll it around until it changes and then we line the hands up.

8-2 [ Sets and aligns the hour hand, spins it around again to make sure it works ]

8-3 - [Scott] See how it instanty flips over? Almost. Need to adjust it.

8-4 [ Adjusts it and tests it again ]

8-5 [Scott] This stuff is for taking fingerprints off

8-6 [ Uses a kneaded gum to remove fingerprints and smudges, carefullty works over the watch ]

8-7 [Scott] There are 2 different kinds, a new kind and old kind. The new kind doesn't leave a film.

8-8 [ Added the minute hand, trying to get them aligned ]

8-9 [Scott] Not all watches have instant change

8-10 [ Auston stops his work to listen to employee complain about the ordering system.] "What can we do about it?" [ Resumes working on watch band ]

8-11 [Steve] You've done [ Bunch of things ] Where are we now?

8-12 [Scott] Lets refinish the case. I'll let this sit and run while we do that.

8-13 [ Auston covers all his work and walks into the jewelry side of the workshop. I meet all of the jewelry repair people. He opens the lid on an ultrasonic bath and pulls out watch parts ]

8-14 [Scott] This is the case disassembled=. We have to clean this stuff after the bath - look at this it's got all kinds of crud in it [ Shows me watch band with little black chunks in it ]. Watch out, this will spit a bit.

8-15 [ We are next to a steam nozzle pointing down. I back away. He holds the watch parts with tongs and holds them individually under the steam, disgusting black stuff falls into catch sink. ]

8-16 [Steve] So that's just human crud up in the band?

8-17 [Scott] We call it Finger Butter.

8-18 [ We laugh ]

8-19 [Scott] This one actually needs a new crystal so we'll put a new one in there. [ he's done ] Now we'll take it back to the buffing room and polish it.

8-20 [ They have a cool room for cleaning with a micro CNC machine and two-sided buffer aparatus]

8-21 [ Scott puts on gloves and shows me the two buffing wheels, Aaron explains the need for the CNC to sometimes make parts ]

8-22 [Scott] The machine has two things, if you look here there's a vacuum. Once side is a high polish side and the other is for satin. This is stainless steel, the band wants to be polished on the edge and satin in the center.

8-23 [ Polishes the case, adding rouge to the buff wheel every 10 seconds ]

8-24 [Scott] As you can see it's starting to become highly polished. We do this until you can't see any pits anymore. We leave this threaded tube here toprotect inner threads while we polish [ points to tube that holds winding stalk ]

8-25 [ Buffs, holds it up to light fordivots, then buffs again ]

8-26 [Scott] We actually have a laser welder the jewelers used, so if they are really deep we fill them with stainless.

8-27 [ We move over to the satin buff and start applying satin to the face of the case ]

8-28 [Steve] Is that the serial # for the watch?

8-29 [Scott] No - that's just a model number

8-30 [ Tells me about how expensive the watches are, he worked on an 80k watch the other day ]

8-31 [Scott] Whoops, the satin kind of went over, so we'll take it back to the smooth buffer and clean it up [ Does it in 2 seconds ]

8-32 [ Explains how he does the band, we are running out of time. ]

8-33 [Scott] Can you polish the crystals?

8-34 [Scott] The acrylic ones you can, the sapphire crystals you can't

8-35 [ Explains to me how they are used on Rolex vs. other watches, aftermarket vs. original ]

8-36 [Steve] What happens if you get a fake one?

8-37 [Scott] We can't work on them. We could lose our account with Rolex - not everyone can get Rolex parts. You have to be authorized to buy parts. There's no such thing as authorized Rolex repair anymore. This is about as far as we are going to get today.